Now that the strongback and station molds are in place, it's time to begin construction. This begins with the inner and outer stems at the bow and stern. Starting here creates an attachment point for the cedar strips at each end.

The stem pieces are cut from white ash, a stronger wood than the cedar strips, but not so hard they become difficult to bend around the mold during the laminating process. The stems bare the brunt of blunt impact anytime the canoe is paddled into a beach, dock, rock, or even another boat, so they need to be strong. Thus, consider not using soft woods such as cedar, pine, or redwood, etc.

Once I ripped the 1/4" strips of white ash from the board, I needed them to be more flexible than they were so they wouldn't crack or break when bent in a sharp curve around the mold. To do this, I placed them all in some PVC pipe and attached it to a kettle where water was boiled until steam passed through the pipe. I blocked the openings with rags. Steam was able to escape, but most of it was trapped inside the pipe with the strips of ash, softening them enough to bend them.

PCV isn't ideal for steaming wood as the heat eventually warps it, but it's all I had to work with at the time.

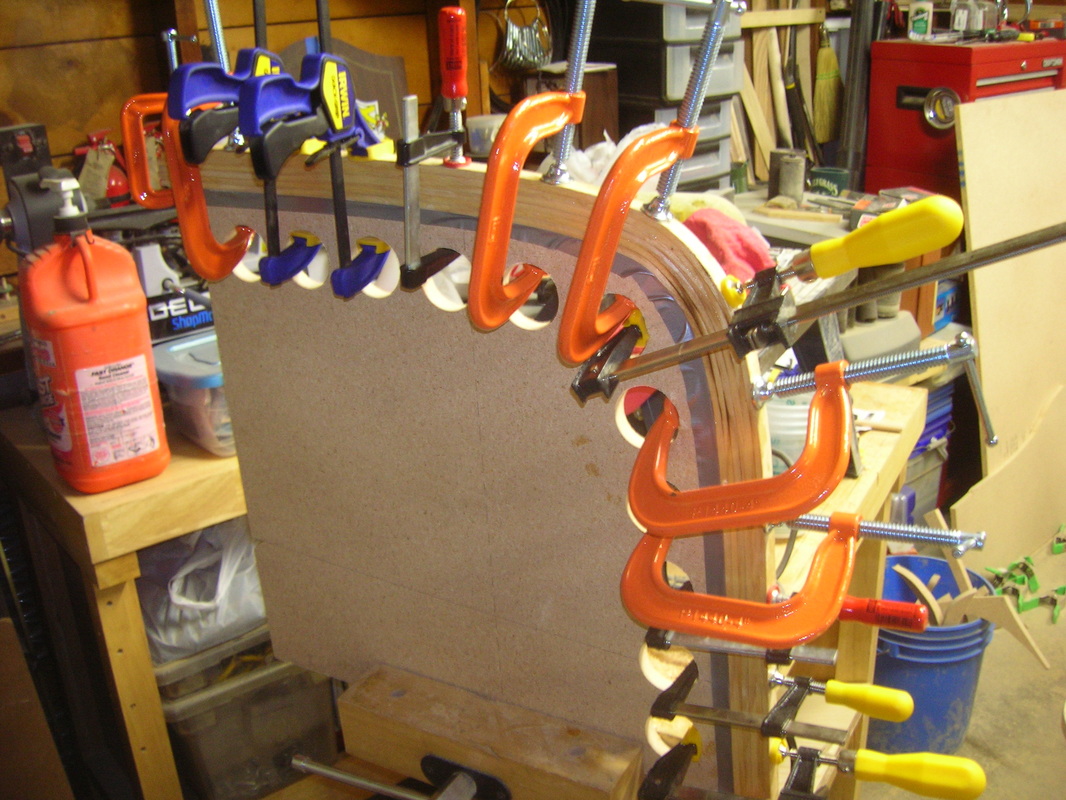

With the wood steamed, I mixed some epoxy and glued each piece together (3 strips for the inner and 3 strips for the outer on each end of the canoe). Wood glue would be fine to use here since the stems will be sheathed in fiberglass when finished, so some may consider epoxy to be overkill. Once both inner and outer stem pieces are glued together, clamp both (one on top of the other) to the mold, but DO NOT glue one to the other, they need to be separate pieces (inner and outer). The one closest to the mold becomes the inner and the one on top of that one becomes the outer stem. They must match up, or nest together perfectly, so clamp them together.

Once the glue has cured, they can be unclamped, then tapered with hand tools. The taper needs to match the curvature of the canoe so the cedar strips rest against the inner stem perfectly.

Once finished, the inner stem is clamped to the canoe mold until enough cedar strips are attached to hold it in place without the clamps. More on that in my next post.

1 Comment

Carl Hildeman

7/5/2017 00:48:33

Good instructions here, but I miss the part where the inner and outer stems are attached. I will keep searching, because I really need to get this absolutely right. My drawing has only five strips. It is an Endeavour.

Reply

Leave a Reply. |

AuthorTrent Denison: Blogger, YouTuber, DIYer, Electronics Repair Technician, Foodie, Cyclist, Runner, Mountain Climber, Entrepreneur, Genuine jack-of-all-trades. ArchivesCategories |

RSS Feed

RSS Feed